Brewery

de glazen toren

Tasty natural beer

From friendship to beer

Introduction

Teacher and beer enthusiast Jef Van den Steen got to know soul mate and lawyer Dirk De Pauw in the late 1980s through municipal politics in Erpe-Mere.

Hobby Brewing

As a hobby, they started brewing their own beer. However, the brews did not have the hoped-for results.

Three-year training

A three-year course for 'brewery-malt-fermentation department' is being followed at the Ghent college CTL (today Hogeschool Gent)

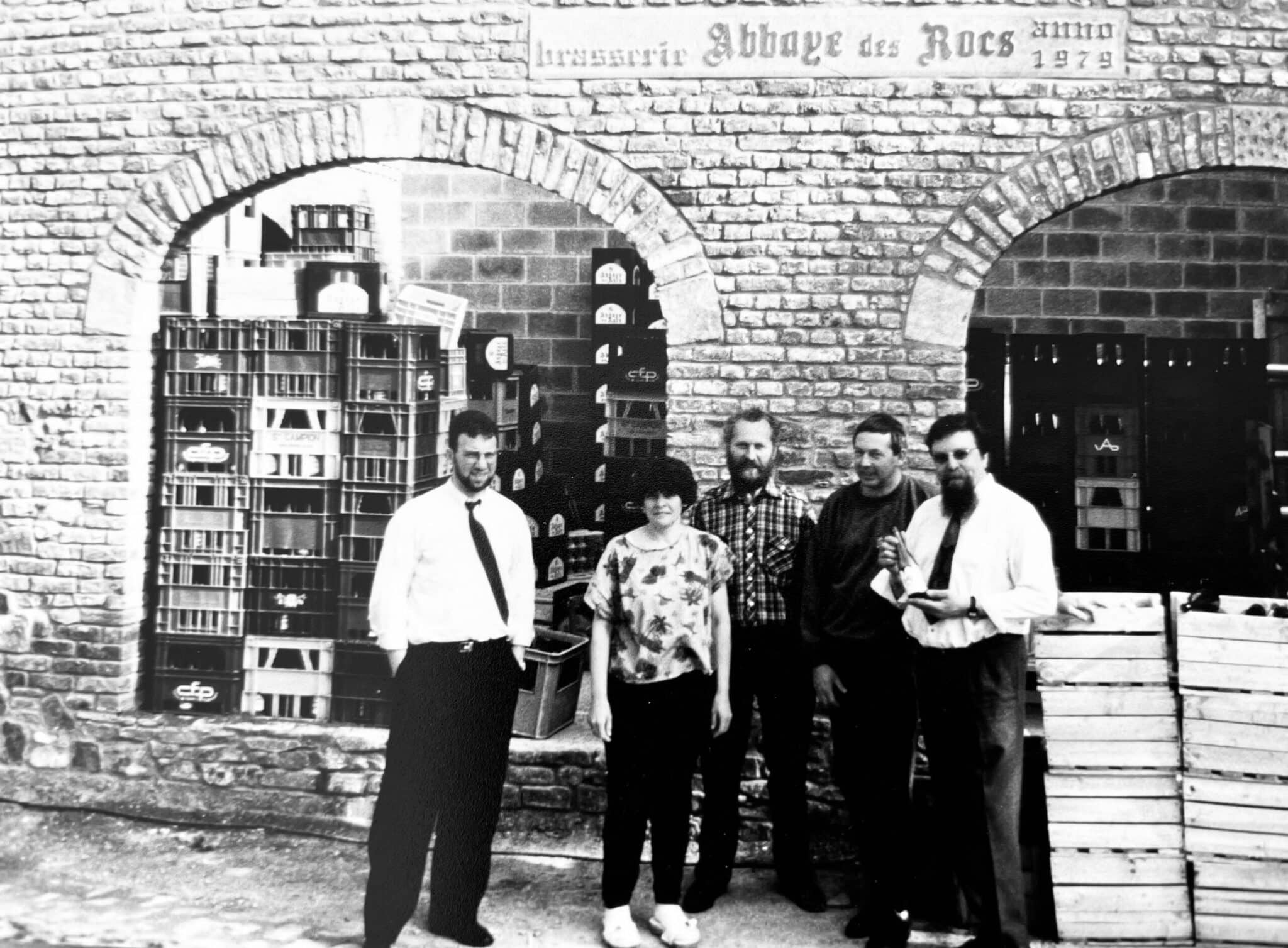

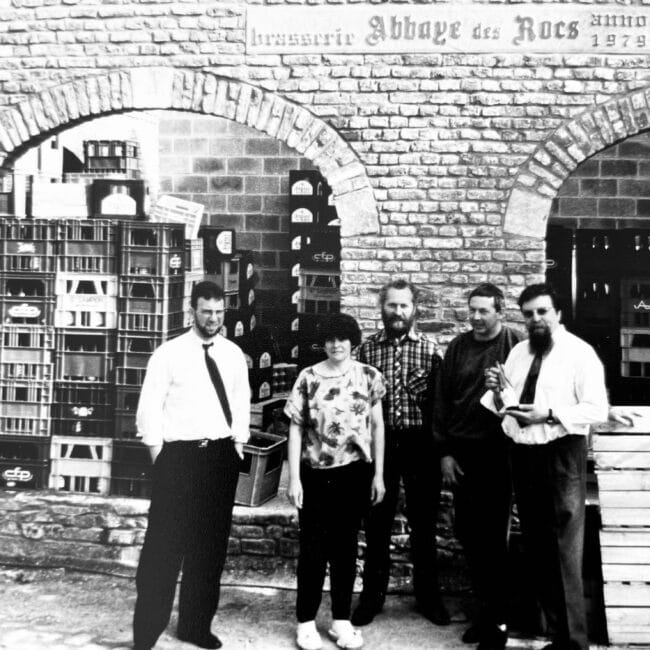

Visits

By way of prospecting, several brewery visits are made.

Company

Finally, the company 'De Glazen Toren' was established in 2002.

BVBA

In 2004, 'de Glazen Toren' was transformed into a proper BVBA with its own small 500-litre plant.

The first beer

The brewery officially launched in 2004 with its first beer, Saison d'Erpe-Mere.

Zythos Beer Festival

Saison d'Erpe-Mere enjoys great success and is picked up by a US importer

German installation

There will be a brand new 25HI. custom-built installation.

Licence

In 2016, a licence was applied for to install 65 Hl cylindroconical fermentation tanks behind the brewery buildings. The permit was refused

Industrial building

In 2019, an industrial building was purchased in AALST ZUID III. The hall was equipped with a fermentation room and a bottling line to sell the beers in specific 33cl bottles.

40 hectolitres

A 40 hectolitre per brew brew room will be installed in the new premises in 2023.

Introduction

Teacher and beer enthusiast Jef Van den Steen got to know soul mate and lawyer Dirk De Pauw in the late 1980s through municipal politics in Erpe-Mere.

Hobby Brewing

As a hobby, they started brewing their own beer. However, the brews did not have the hoped-for results.

Three-year training

A three-year course for 'brewery-malt-fermentation department' is being followed at the Ghent college CTL (today Hogeschool Gent)

Visits

By way of prospecting, several brewery visits are made.

Company

Finally, the company 'De Glazen Toren' was established in 2002.

BVBA

In 2004, 'de Glazen Toren' was transformed into a proper BVBA with its own small 500-litre plant.

The first beer

The brewery officially launched in 2004 with its first beer, Saison d'Erpe-Mere.

Zythos Beer Festival

Saison d'Erpe-Mere enjoys great success and is picked up by a US importer

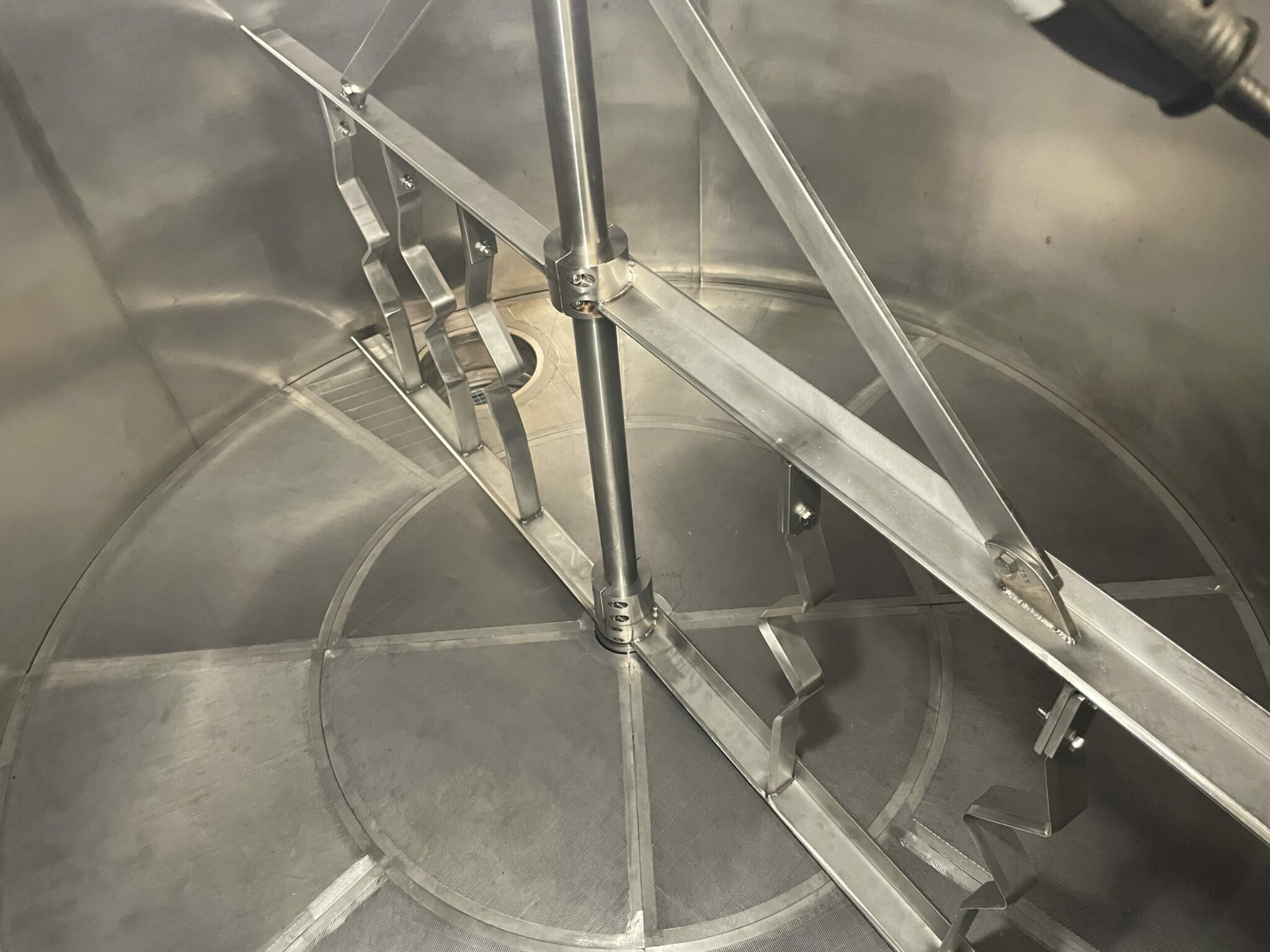

German installation

There will be a brand new 25HI. custom-built installation.

Licence

In 2016, a licence was applied for to install 65 Hl cylindroconical fermentation tanks behind the brewery buildings. The permit was refused

Industrial building

In 2019, an industrial building was purchased in AALST ZUID III. The hall was equipped with a fermentation room and a bottling line to sell the beers in specific 33cl bottles.

40 hectolitres

A 40 hectolitre per brew brew room will be installed in the new premises in 2023.

An overview of our beers

Discover our full range of beers below.

Founded

Export

Different beers

Countries

Employees

From grain to beer

Malts

Cleaned and purified grain (usually barley or wheat) is soaked in the malting plant, then germinated and finally dried or roasted. In the brewery, the malt grains are milled (crushed).

Cooking with the addition of hops

In the brewery, the malt is mixed with hot water in several temperature steps to form a mash. Afterwards, the chaff is filtered out and the clear liquid (wort) is boiled with hops for about an hour and a half.

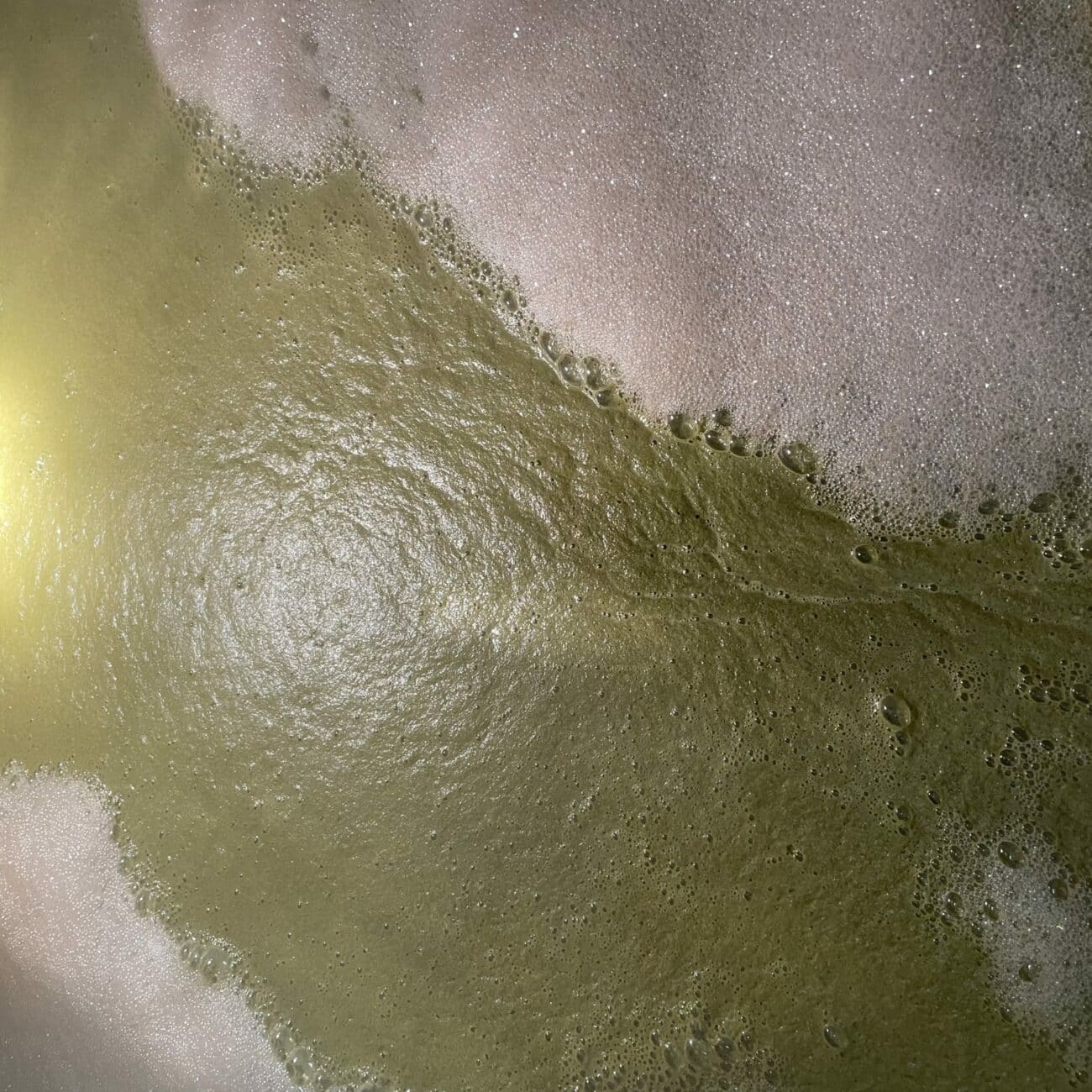

Fermentation

Via a counterflow chiller, the boiled wort is cooled to 22°C, and pumped to a fermentation tank. Yeast is added. The yeast converts the sugars in the wort into alcohol and carbon dioxide. After about eight days, the young beer is lagered at a lower temperature.

Bottling

The clarified young beer is infused with a small amount of sugar and fresh yeast in a filling tank. It is bottled in bottles, cans or barrels of various types. Fermentation gives the beer a stable head and bubbles in the glass.

Malts

Cleaned and purified grain (usually barley or wheat) is soaked in the malting plant, then germinated and finally dried or roasted. In the brewery, the malt grains are milled (crushed).

Cooking with the addition of hops

In the brewery, the malt is mixed with hot water in several temperature steps to form a mash. Afterwards, the chaff is filtered out and the clear liquid (wort) is boiled with hops for about an hour and a half.

Fermentation

Via a counterflow chiller, the boiled wort is cooled to 22°C, and pumped to a fermentation tank. Yeast is added. The yeast converts the sugars in the wort into alcohol and carbon dioxide. After about eight days, the young beer is lagered at a lower temperature.

Bottling

The clarified young beer is infused with a small amount of sugar and fresh yeast in a filling tank. It is bottled in bottles, cans or barrels of various types. Fermentation gives the beer a stable head and bubbles in the glass.

Curious to find out more about us?

Reviews

No posts were found for provided query parameters.